Products

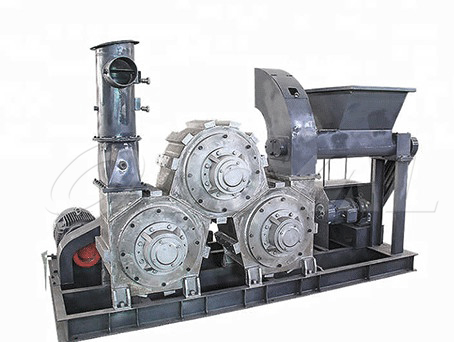

The powder surface modifying machine(also called coating machine) is widely used in the fields of non-metal stuffing or pigment like plastic, rubber, adhesive, macromolecule materials, high polymer composite, functional materials and dope industries and so on; It can not only improve the compatibility of both non-organic mineral stuff and organic high polymer, enhance binding force of interfaces, rise the mechanical strength and comprehensive ability, but also increase the stuffing ability of powder, save product cost as well.

Applications: Mining, building materials, chemicals, metallurgy and other industries.

E-mail: joyal@crusherinc.com

The powder surface treatment is completed mainly by means of three modifying chamber; the dry powder and dosed agent are fed into the chambers synchronously, with high-speed rotation in the form of fluidizing vortex.the modification is completed with the heat generated by high speed shearing, colliding and friction between the rotor and powder.

| Model | SLG-3/300 | SLG-3/450 | SLG-3/600 | SLG-3/900 |

| Main Power (kw) | 18.5kw×3 | 30kw×3 | 37kw×3 | 75kw×3 |

| Blower power(kw) | 7.5kw | 22kw | 22kw | 30kw |

| Rotation speed of shaft(rpm) | 4500rpm | 3600rpm | 2700rpm | 2000rpm |

| Capacity(t/h) | 500-1500kg/h | 1500-3000kg/h | 3000-4500kg/h | 5000-9000kg/h |

©2021 Shanghai Joyal Machinery Co., Ltd. All Rights Reserved.